Do you remember how the local vegetable and fruit market in your neighborhood looks like? It will be difficult to recall as we have not stepped outside our house for more than a year. But you can imagine the wastage of vegetables in those markets.

India struggles with its position in the Global Hunger Index, 2020 (ranking 94 out of 107 countries), and wastage of agricultural produce is one major reason. According to Financial Express, a whopping 16% of produced fruits and vegetables are wasted every year. This is due to various problems in supply chain management.

Ninjacart: Inception and journey till now

To tackle the problem of agricultural produce wastage, Thirukumaran Nagarajan, along with his friends, started Ninjacart. At first, they wanted to solve the problem by helping retailers take their inventory online and delivering in less than 60 minutes from ordering.

But soon they encountered different problems in this business model,

- Customers were unwilling to pay a premium price for just the convenience of ordering online.

- Supply chain issues crept up with the inability to track real-time demand and manage inventory.

With all these problems, the team realized that while there was a demand for the service, the supply side had many inefficiencies associated with it to fulfill it. Hence, they decided to pivot from the demand side to the supply side and build a fast B2B supply chain for agricultural produce leveraging data.

According to Inc42 Analysis on India’s Agritech Landscape, the addressable market opportunity in 2020 was $ 24.1 Bn out of which only $ 204 Mn was tapped (~1% of the overall potential was tapped). This gives us a view of what Ninjacart and other agritech startups can achieve in the future.

The startup was founded in 2015 in Bangalore, India. The last funding round (series C) happened in October 2020, in which Ninjacart raised $ 49.7 Mn with a valuation of $ 503 Mn. The total funding till now is $ 213 Mn. Ninjacart’s revenues stood at $ 59.1 Mn as of December 2019.

The company has grown significantly since its inception. In 2016, Ninjacart was handling only 7 tonnes a day, and now the daily volume is close to 1400 of vegetables and fruits from farm to retailers in just less than 12 hours and serves around 17000+ retailers across 7 major cities in India – Bangalore, Chennai, Hyderabad, Ahmedabad, Pune, Mumbai, and Delhi. And, they have been doing this with a delivery accuracy of 99.88 percent all year round. What business model makes Ninjacart so successful?

Ninjacart Business Model

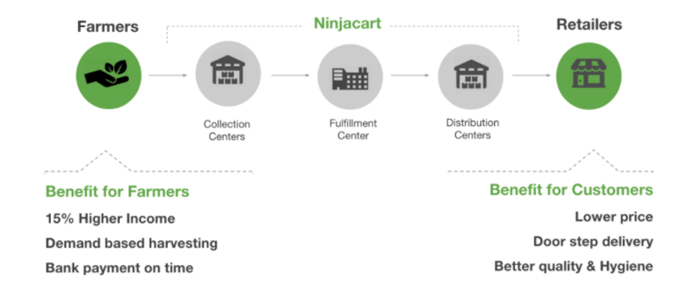

Ninjacart deals with the problem of inefficiencies in the supply chain by connecting farmers with retailers and trying to remove the middlemen benefitting all the stakeholders in the process (farmers, retailers and customers).

Farmers are directly connected with the retailers, helping them get better deals. Simultaneously retailers are able to get fresh produce which helps them to serve their customers.

According to the co-founder and CEO, Thirukumaran Nagarajan, one of the biggest problems they have encountered is farmers not getting a fair price for their products. They are trying to solve this problem by implementing a supply chain that leverages data, technology, and a logistics network built from scratch as solutions like this don’t exist in the market.

Ninjacart Creating a data-enabled supply chain

Thirukumaran Nagarajan and the team did not have the expertise in the supply chain, and in hindsight, that was a blessing in disguise. This helped them to create a supply chain solution blending data and technology tailored for India.

With this model, Ninjacart was able to supply fresh produce to the retailers and customers with hygiene and quality.

There are specific problems that Ninjacart addressed with their data-enabled supply chain

- End-to-end traceability on the supply chain: Every box or cart in the CC’s, FC’s, and DC’s at Ninjacart has RFID (Radio Frequency Identification) tags attached. This has led to a strong brand establishment and continued trust.

- Forecasting demand: Ninjacart’s long-term vision is to improve efficiency in the supply chain and reduce wastage in transit. For this, they have beautifully used technology such as Data Science, Artificial Intelligence, Machine Learning to forecast demands. Their predictive model takes many factors not limited to historical data, future expectation, weather forecast data to predict weekly numbers at SKU (Stock Keeping Unit) levels to minimize errors as far as possible. This is the reason they have been able to maintain a 0.2% – 0.3% error rate for the past six years.

- Educating farmers about the expectation: Using the technology and data available, Ninjacart educates them on the expectation which benefits both the parties (farmers on the prices and amounts to harvest and Ninjacart to reduce wastage)

Grassroot level supply chain innovations and Awards

Over the years, the B2B agritech startup has been refining and innovating processes on a grassroot level to optimize their efficiency. These might seem trivial but have given them great results.

- To reduce the time at the stops, the employees don’t wait for the boxes to be emptied. The carts are picked up when vehicles are returning after making the drop. Since the carts are RFID tagged, it doesn’t have to go to the same distribution center

- Ninjacart has adopted the use of “dolleys” instead of traditional methods which helps them load and unload the boxes in the fulfillment centers

With these innovations and creating a robust data-enabled supply chain, Ninjacart has won many awards in the agritech category.

Increasing brand visibility with social impact: A win-win

While the startup has aced the game of building technology and data enabled supply chain, there is another initiative taken by Ninjacart which shows how great business can create a huge social impact. In 2020 when the whole world struggled with a pandemic caused by the deadly Coronavirus, Ninjacart stepped up to solve the problem of their comrades, the farmers of India.

As the whole country went into lockdown, local vegetable and grocery stores also got closed. This affected the farmers a lot. To solve this problem, Ninjacart launched an initiative named HTF (Harvest the Farms), where the customers could directly buy from the farmers at a cheaper price.

With the help of their technology-enabled processes, Ninjacart identified the excess produce and buy it from the farmers at a price that covered their cost. Then it sold those produce to customers at a lower price to reduce the wastage. This has definitely put Ninjacart on everybody’s radar and the team deserves brownie points for quick thinking and creating a beautiful solution to tackle the problems of the nation’s backbone, the farmers.

Promising and exciting future of unique business model of Ninjacart

Reduction of agricultural produce wastage has always been on the forefront of Ninjacart’s vision. But, along the way the team realized that food safety is a bigger problem. In 2018, the startup adopted the vision of providing “Safe food for one billion”.

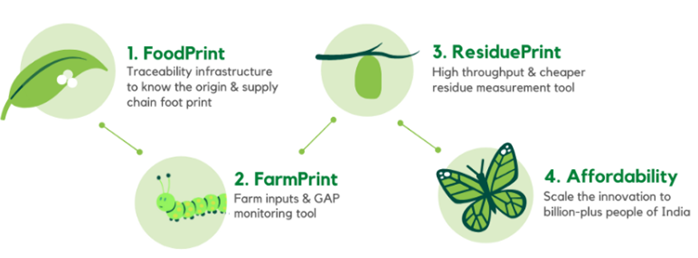

Ninjacart aims to provide “zero residue food” (having a low maximum residue limit (MRL)) and has started to invest in technology. The startup has beautifully divided into four different steps and named them FoodPrint, FarmPrint, ResiduePrint, Affordability.

They have already launched FoodPrint on World food safety day (June 7, 2020) to better view the whole supply chain and trace where the produce is coming from.

The startup is currently working on the beta phase of developing FarmPrint, which will help them get nearer to producing zero residue food. Leveraging technology, they will be able to monitor the whole process better.

ResiduePrint is in its early stage of development, and the startup is trying to make the solutions durable and scalable.

A startup with an aim to create a strong societal impact, we are eager to witness the business and technological prowess that the Ninajcart team displays in the future.

-AMAZONPOLLY-ONLYWORDS-START-

Also, check out our most loved stories below

Why did Michelin, a tire company, decide to rate restaurants?

Is ‘Michelin Star’ by the same Michelin that sells tires, yes, it is! But Why? How a tire company evaluations became most coveted in the culinary industry?

Bajaj Auto: The Story of an Indian Born Global Brand

Bajaj Auto has evolved tremendously over time from its traditional scooter Chetak to having the trendiest bike Pulsar. It has managed to stay relevant.

Jio’s Offensive Marketing Warfare: From Challenger to Leader

In just 4 years Reliance Jio has become the Indian telecom market leader due to its marketing warfare strategies. What is this strategy and how Jio used it?

Johnnie Walker – The legend that keeps walking!

Johnnie Walker is a 200 years old brand but it is still going strong with its marketing strategies and bold attitude to challenge the conventional norms.

Flipsters: Creating the Butterfly effect in Indian Startup Ecosystem

How is it that ex-Flipkart employees or Flipsters as they call themselves have achieved such massive success in the Indian Startup Ecosystem?

Nike doesn’t sell shoes. It sells an idea!!

Nike has built one of the most powerful brands in the world through its benefit based marketing strategy. What is this strategy and how Nike has used it?

Domino’s is not a pizza delivery company. What is it then?

How one step towards digital transformation completely changed the brand perception of Domino’s from a pizza delivery company to a technology company?

Why Indians love Old Monk? What is the revival plan of the dying brand?

Indians especially armed forces and college students for generations have loved Old Monk. What makes this rum so special? It’s classy, dark yet affordable.

IKEA- The new master of Glocalization in India?

IKEA is a global giant. But for India, the brand modified its business strategies. The adaptation strategy by a global brand is called Glocalization

-AMAZONPOLLY-ONLYWORDS-END-